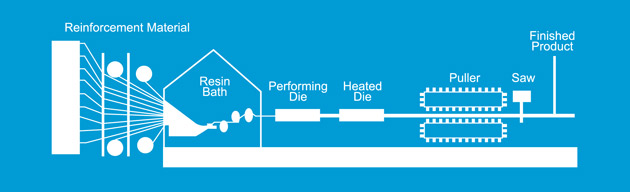

Pultruded Gratings

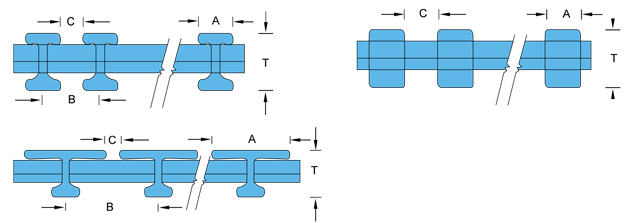

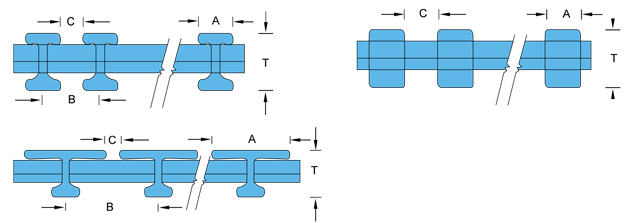

ZeAll pultruded gratings are panels with open space, assembled, through specially designed process, with“ I” ,“ T” and“ HL” shaped bearing bars and interlocked with solid rods or tubes, which are all pultruded.

ZeAll pultruded grating is with light-weight, strong, anti-fire chemical and UV resistant, and reduces costly maintenance.We passed USCG Level 2. ZeAll pultruded grating is well suited for highly corrosive environments and offers extended life, eliminating periodic maintenance and extra cost, which is a good alternative compared to steel gratings.

Advantages of Pultruded grating:

● High anti-fire

● High anti-corrosion and anti-aging

● High anti-slippery

● Light but high loaded strength

● Long service life and maintenance free

● Non-conduction or magnetic

● Easy installation and rich colors

● Various sizes and colors available

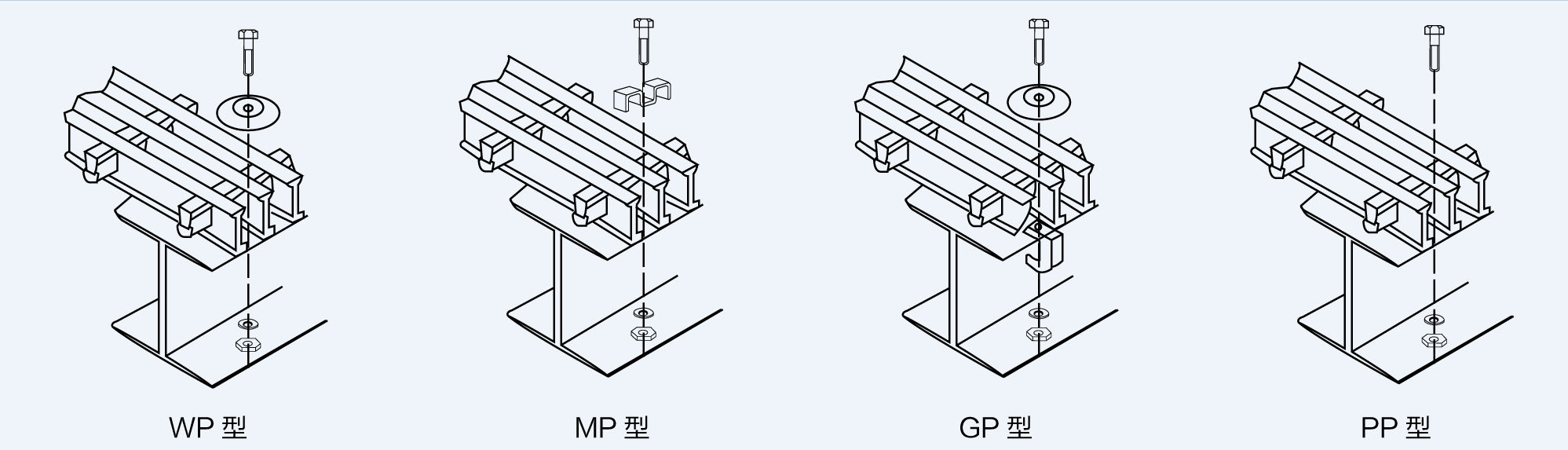

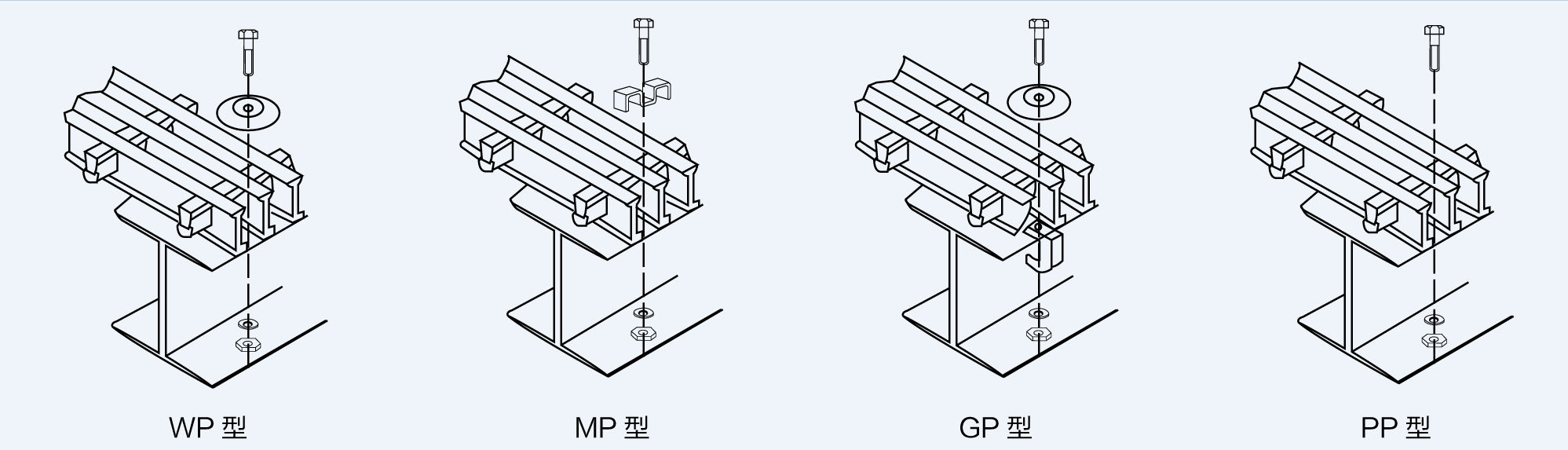

Installation Fixing for Pultruded Gratings

|

Type

|

Height Inch

(mm)

|

Top edge width

(mm)

|

Space between

(mm)

|

Clearance width

(mm)

|

Open area (%)

|

Estimated weight

Kg/m2

|

|

I-4010

|

25

|

15

|

25

|

10

|

40

|

17.1

|

|

I-5010

|

25

|

15

|

30

|

15

|

50

|

14.2

|

|

I-6010A

|

25

|

15

|

38

|

23

|

60

|

11.2

|

|

I-6010B

|

25

|

8

|

19.8

|

11.8

|

60

|

12.2

|

|

I-4015

|

38

|

15

|

25

|

10

|

40

|

22

|

|

I-5015

|

38

|

15

|

30

|

15

|

50

|

19.1

|

|

I-6015

|

38

|

15

|

38

|

23

|

60

|

16.2

|

|

I-4012

|

30

|

15

|

25

|

10

|

40

|

18.8

|

|

I-5012

|

30

|

15

|

30

|

15

|

50

|

15.7

|

|

I-6012

|

30

|

15

|

38

|

23

|

60

|

12.6

|

|

I-40125

|

32

|

15

|

25

|

10

|

40

|

19.8

|

|

I-50125

|

32

|

15

|

30

|

15

|

50

|

17.4

|

|

I-60125

|

32

|

15

|

38

|

23

|

60

|

13.5

|

|

I-4020

|

50

|

15

|

25

|

10

|

40

|

28.5

|

|

I-5020

|

50

|

15

|

30

|

15

|

50

|

24.2

|

|

I-6020

|

50

|

15

|

38

|

23

|

60

|

20.1

|

|

T-1210

|

25

|

38

|

43.4

|

5.4

|

12

|

14.5

|

|

T-1810

|

25

|

38

|

50.8

|

9.5

|

18

|

13.8

|

|

T-2510

|

25

|

38

|

50.8

|

12.7

|

25

|

12.3

|

|

T-3310

|

25

|

41.3

|

19.7

|

61

|

33

|

11.2

|

|

T-3810

|

25

|

38

|

61

|

23

|

38

|

10.2

|

|

T-1215

|

38

|

38

|

43.3

|

5.2

|

12

|

19.6

|

|

T-2515

|

38

|

38

|

50.8

|

12.7

|

25

|

16.7

|

|

T-3815

|

38

|

38

|

61

|

23

|

38

|

14.2

|

|

T-3320

|

50

|

25.4

|

38.1

|

12.7

|

33

|

20.3

|

|

T-5020

|

50

|

25.4

|

50.8

|

25.4

|

50

|

15.7

|

|

HL-4020

|

50

|

15

|

10

|

10

|

40

|

70.4

|

|

HL-5020

|

50

|

15

|

15

|

15

|

50

|

52.2

|

|

HL-6020

|

50

|

15

|

23

|

23

|

60

|

43.5

|

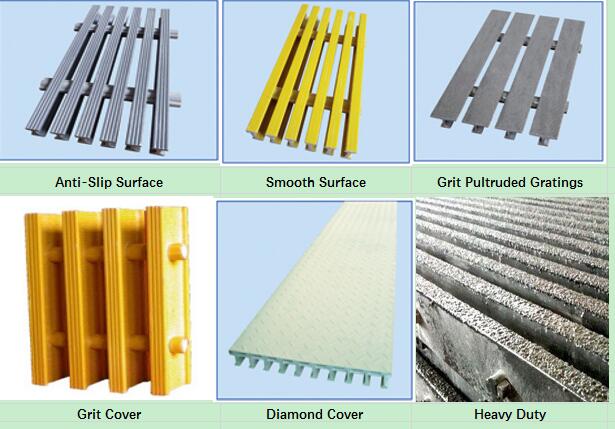

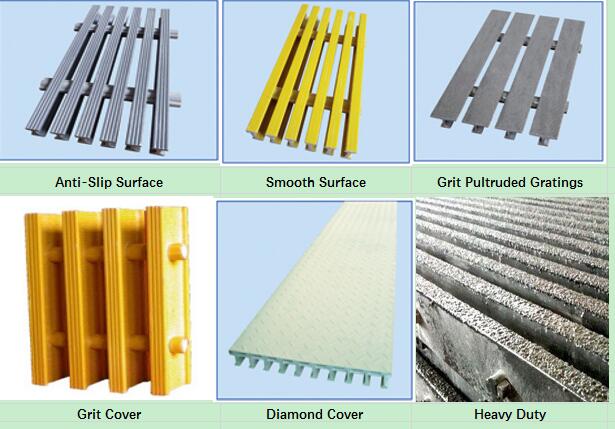

Pultruded Grating Surface:

FRP Molded Grating

FRP Molded Grating